Exploring How Hydrocolloids Affect Food Shear, Compression, or Extension

SUBSCRIBE TO OUR BLOG

Promotions, new products, and recipes.

Hydrocolloids are widely used in the food industry as functional ingredients due to their ability to modify food texture and improve stability. Their effect on food shear, compression, and extension is particularly important as these properties significantly influence mouthfeel, appearance, and overall quality.

Hydrocolloids are complex molecules that exhibit unique rheological properties, such as viscosity, gelation, and hydration capacity, making them ideal for modifying food texture. They can interact with food at different stages of processing and affect the physical and chemical properties of the final product. Therefore, understanding the impact of hydrocolloids on food shear, compression, and extension is crucial for optimizing food formulations and improving consumer satisfaction.

Key Takeaways:

- Hydrocolloids are functional ingredients that modify food texture and improve stability

- Food shear, compression, and extension are important properties that affect mouthfeel and overall quality

- Hydrocolloids exhibit unique rheological properties that make them ideal for textural modification

- Hydrocolloids can interact with food at different processing stages and affect the physical and chemical properties of the final product

- Understanding the impact of hydrocolloids on food texture is crucial for optimizing food formulations and improving consumer satisfaction

Understanding Hydrocolloids and Their Functionality

Hydrocolloids are functional ingredients that are widely used in food products to modify texture, enhance stability, and improve overall quality. These natural or synthetic substances have unique properties that allow them to interact with water and other food components, forming gels or thickening solutions.

Hydrocolloids can have various effects on food, depending on their properties and concentration. They can influence viscosity, elasticity, adhesion, emulsion stability, and other rheological parameters that affect texture and mouthfeel.

There are numerous types of hydrocolloids, each with its specific functionality and impact on food. Some common examples include:

| Hydrocolloid | Function |

|---|---|

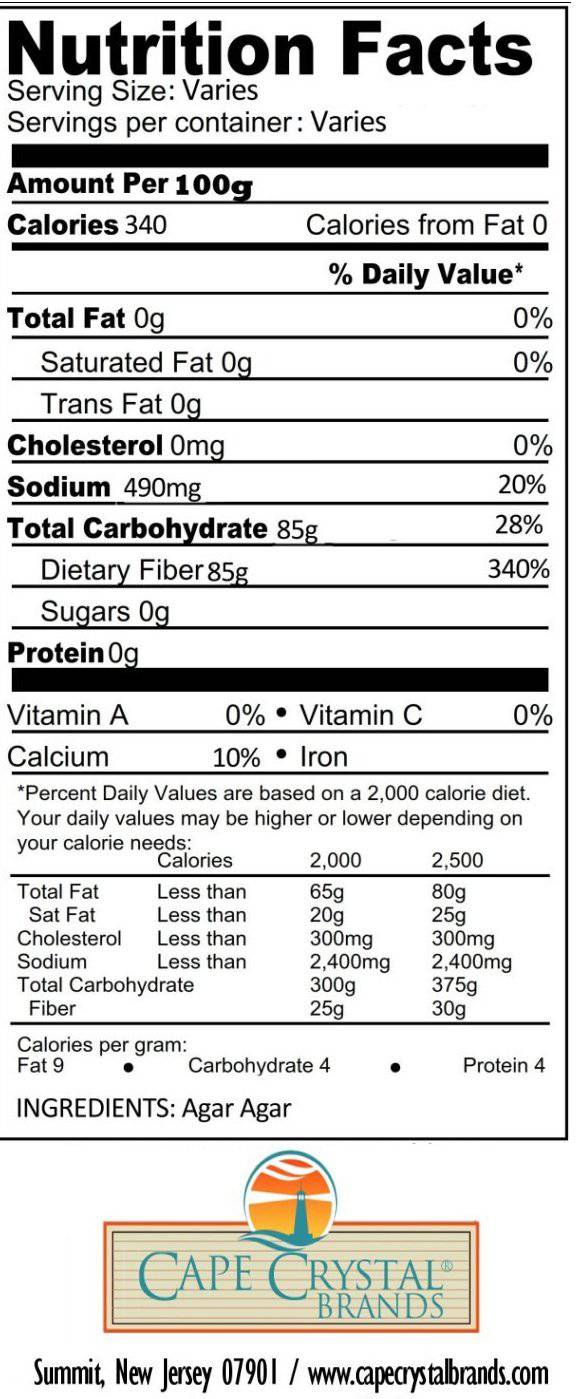

| Agar | Forms firm and brittle gels at low concentrations; stable under acidic conditions |

| Alginate | Forms elastic and semi-rigid gels in the presence of calcium ions; used in low-fat and low-calorie products |

| Carrageenan | Forms strong and flexible gels at low concentrations; enhances water holding capacity and viscosity |

| Gellan Gum | Forms firm and transparent gels at low concentrations; resistant to heat and acid |

| Xanthan Gum | Forms thick and pseudoplastic solutions at low concentrations; improves mouthfeel and emulsion stability |

| Pectin | Forms gels and thickens solutions under acidic conditions; enhances juiciness and flavor release |

Each hydrocolloid has a unique combination of chemical structure, molecular weight, charge density, and other properties that affect its functionality. Hydrocolloid blends are often used in food products to achieve specific textural attributes or stability requirements.

Understanding the functionality of hydrocolloids is essential for food scientists and technologists to design and optimize food formulations. By selecting the appropriate hydrocolloids and their concentrations, food processors can create products with desired textures, sensory properties, and shelf life.

Hydrocolloid Effects on Food Texture

The ability of hydrocolloids to modify food texture is one of their primary uses in food products. By influencing the rheological properties of food systems, hydrocolloids can alter attributes such as viscosity, elasticity, chewiness, and creaminess.

For example, adding xanthan gum to a salad dressing can increase its viscosity and improve its clinginess to vegetables, enhancing the overall mouthfeel. Incorporating carrageenan in a dairy product can create a creamy and smooth texture, reducing the perception of ice crystals or whey separation.

The texture modification potential of hydrocolloids depends on various factors, such as the type of hydrocolloid, its concentration, the processing conditions, and the nature of the food matrix. Optimizing these parameters requires an understanding of the underlying mechanisms of hydrocolloid effects and their interactions with other food components.

In the next section, we will explore the specific effects of hydrocolloids on food shear and how they can affect food texture.

Shear and Hydrocolloid Interactions

When hydrocolloids are introduced into foods, they can significantly impact the rheological behavior of the food during shear. Hydrocolloids can influence parameters such as shear stress, shear rate, and viscosity, leading to changes in texture and mouthfeel.

The effects of hydrocolloids on food shear are dependent on the properties of the hydrocolloid. For example, the viscosity of a hydrocolloid can affect the rate of deformation during shear. Higher viscosity hydrocolloids can lead to greater resistance to deformation, resulting in increased firmness and reduced spreadability of the food. On the other hand, lower viscosity hydrocolloids can cause the food to flow more freely during shear, resulting in decreased firmness and increased spreadability.

Hydrocolloids can also influence the thixotropic behavior of foods during shear. Thixotropy is the property of a material to become less viscous when subjected to shear, followed by a return to its original viscosity when the shear stress is removed. Some hydrocolloids, such as xanthan gum, can increase the thixotropic behavior of food. This can result in foods that are easier to spread but can maintain their shape and hold their form better once the shear stress is removed.

Overall, the interaction between hydrocolloids and food shear is complex and multifaceted. To fully understand the impact of hydrocolloids on food shear, it is important to consider the specific properties of the hydrocolloid used and the desired attributes of the final food product.

Compression and Hydrocolloid Effects

Compression testing is a common method used to evaluate the mechanical properties of food. Hydrocolloids can impact the compressibility of food, affecting attributes such as firmness and elasticity.

The influence of hydrocolloids on food compression depends on several factors, including the type and concentration of the hydrocolloid used, as well as the food matrix. For instance, xanthan gum has been reported to increase the compressive modulus of gels, while carrageenan has been found to decrease it.

The effects of hydrocolloids on food compression can be explained by their ability to modify the rheological properties of the food matrix. Hydrocolloids can alter the viscoelastic behavior of food, contributing to changes in its mechanical response to compression.

Applications of hydrocolloids in food compression include the production of dairy products, such as cheese and yogurt, as well as bakery products, such as bread and cakes. For instance, in cheese making, hydrocolloids are used to improve the texture and reduce the syneresis of the final product. In bread making, hydrocolloids are used to improve dough stability and reduce staling.

Overall, hydrocolloids can play a critical role in modifying the compressibility of food, leading to improved texture and stability. Understanding the influence of hydrocolloids on food compression is essential for formulating food products with desirable mechanical properties.

Extension and the Role of Hydrocolloids

In the context of food science and technology, extension refers to the ability of a food material to stretch or elongate without breaking. Hydrocolloids can play a significant role in modifying food extension properties, ultimately improving texture and mouthfeel.

Hydrocolloids are commonly used to enhance the stretchability and elasticity of food, leading to desirable textural attributes. They can also help improve the overall quality of food products by preventing undesirable changes during storage and distribution.

Depending on the type of hydrocolloid used, different effects can be observed on food extension. For example, xanthan gum can contribute to improved elasticity, while carrageenan can enhance stretchability. Other hydrocolloids, such as pectin and alginate, can provide a combination of both effects.

Food products that can benefit from hydrocolloid modification of extension properties include dairy products, sauces, and dressings, as well as bakery and confectionery items. Hydrocolloids can help create a desirable texture and improve the overall mouthfeel of these products.

For instance, in ice cream production, hydrocolloids such as locust bean gum can help prevent the formation of ice crystals and improve the smoothness of the final product. Similarly, in the production of bakery items such as bread, hydrocolloids can aid in dough formation and improve texture.

Hydrocolloid Effects on Food Texture

In this section, we will explore the broader impact of hydrocolloids on food texture. Hydrocolloids are widely used as texture-modifying agents in the food industry due to their unique properties that can alter the structure and mouthfeel of food. The viscosity of hydrocolloids can affect the thickness and creaminess of food, while their gel-forming ability can create a firm and cohesive texture. Additionally, hydrocolloids' hydration capacity can impact the water content of food and its overall texture.

Hydrocolloids are commonly used in various food products, including dairy, bakery, meat, and sauces. For instance, carrageenan, a sulfated polysaccharide derived from red seaweed, is used in dairy applications to prevent whey separation and improve texture. Similarly, xanthan gum, a microbial polysaccharide, is used in bakery products to enhance dough elasticity and improve volume.

The choice of hydrocolloid for a particular application depends on the desired texture, processing conditions, and cost. Moreover, the interaction between hydrocolloids and other ingredients, such as proteins and minerals, can affect food texture and functionality. For example, the addition of hydrocolloids may increase the water-binding capacity of proteins, resulting in a firmer and juicier texture in meat products.

Overall, hydrocolloids play a crucial role in modifying food texture and enhancing its sensory properties. The diverse range of hydrocolloid properties offers a broad spectrum of texture-modifying capabilities, making them essential ingredients in the food science and technology field.

Hydrocolloids and Food Stability

Hydrocolloids play a crucial role in improving food stability. Their unique properties, such as their ability to form gels, thicken, and bind water, make them valuable ingredients in many food systems.

Hydrocolloids can help stabilize emulsions by preventing oil and water from separating, thus extending the shelf life of various food products. They can also reduce the formation of ice crystals in frozen foods, preventing freezer burn.

In addition, hydrocolloids can prevent syneresis, which is the separation of liquid and solid components in food. This can occur in products such as cheese, yogurt, and sauces. Hydrocolloids can bind the liquid and solid components together, preventing separation and improving the texture and mouthfeel of the final product.

Examples of hydrocolloids commonly used for improving food stability include pectin, carrageenan, xanthan gum, and locust bean gum. Each of these hydrocolloids has unique properties that make them suitable for specific applications and food products.

Case Study: The Use of Hydrocolloids in Yogurt

"Hydrocolloids are commonly used in yogurt production to improve texture and stability. Pectin is often added to prevent whey separation and improve firmness. Carrageenan can also be used to enhance the creamy mouthfeel and prevent syneresis. Additionally, xanthan gum is used to thicken yogurt and improve texture."

This case study demonstrates the importance of hydrocolloids in improving the stability and texture of yogurt, a popular and widely consumed food product. By using hydrocolloids, manufacturers can produce yogurt that maintains its texture and consistency throughout its shelf life, providing consumers with a high-quality product.

Hydrocolloids in Food Formulation and Processing

Hydrocolloids are widely used as functional ingredients in food formulation and processing. Their unique properties, such as viscosity, gelation, and water-binding capacity, make them valuable tools for achieving desired textural attributes and stability in food products. In food science and technology, hydrocolloids play an essential role in creating a wide range of food products, from sauces and dressings to baked goods and dairy products.

When formulating food products, it is essential to choose the appropriate hydrocolloid based on the desired functional properties and target application. For example, xanthan gum and carrageenan are often used in dairy products to improve texture and prevent syneresis, while methylcellulose and hydroxypropyl methylcellulose are used in bakery products to control moisture and improve dough stability.

Processing techniques such as shear and temperature can also impact the performance of hydrocolloids in food products. For example, high shear processing can lead to the breakdown of large hydrocolloid molecules, resulting in reduced viscosity and gel strength. Therefore, it is essential to understand the impact of processing conditions on hydrocolloid functionality and adjust formulations accordingly.

Hydrocolloids can be added to food formulations in various forms, including powders, solutions, and gels. The amount and type of hydrocolloid used can significantly impact the final product's texture and stability. Therefore, careful consideration and testing are necessary to determine the optimal hydrocolloid formulation for a specific application.

In conclusion, hydrocolloids are essential functional ingredients in food formulation and processing, providing texture modification and stability enhancement. Understanding the impact of hydrocolloids on food science and technology is crucial for creating high-quality, consistent, and stable food products.

Conclusion

In conclusion, the impact of hydrocolloids on food texture, stability, and overall quality has been demonstrated through various studies and applications. Hydrocolloids can modify food shear, compression, and extension, leading to changes in texture and mouthfeel, while also improving stability by preventing syneresis and stabilizing emulsions.

It is important for food industry professionals to understand the unique properties of different hydrocolloids and their impact on food systems. By leveraging hydrocolloid properties such as viscosity, gel formation, and hydration capacity, it is possible to achieve desired textural attributes and stability in food products.

As such, the role of hydrocolloids in food formulation and processing cannot be overstated. By incorporating hydrocolloids into product development, food manufacturers can improve the sensory experience of food while also ensuring product stability and quality over time.

Key Takeaways:

- Hydrocolloids can modify food shear, compression, and extension, leading to changes in texture and mouthfeel.

- Hydrocolloids improve stability by preventing syneresis and stabilizing emulsions.

- Understanding the unique properties of different hydrocolloids is crucial for food industry professionals.

- By leveraging hydrocolloid properties, desired textural attributes and stability can be achieved in food products.

- Hydrocolloids are essential in food formulation and processing for improving sensory experience and product quality over time.

FAQ

What are hydrocolloids?

Hydrocolloids are substances that have the ability to form gels or thicken liquids when dispersed in water or other solvents. They are commonly used in the food industry as functional ingredients for their texture-modifying and stability-enhancing properties.

How do hydrocolloids affect food shear?

Hydrocolloids can modify the rheological behavior of food during shear, leading to changes in texture and mouthfeel. They can enhance viscosity and provide resistance to flow, resulting in a thicker and more viscous product.

What impact do hydrocolloids have on food compression?

Hydrocolloids can influence the compressibility of food, affecting attributes such as firmness and elasticity. They can improve the ability of food to resist deformation under compression, resulting in a more stable and less prone to collapse product.

How do hydrocolloids affect food extension?

Hydrocolloids can enhance the stretchability and elasticity of food, leading to improved texture and mouthfeel. They can contribute to a more cohesive and resilient product, allowing it to withstand stretching without breaking or tearing easily.

How do hydrocolloids impact food texture?

Hydrocolloid properties such as viscosity, gel formation, and hydration capacity can influence the overall texture of food. They can contribute to attributes such as creaminess, thickness, and smoothness, enhancing the sensory experience of the product.

How do hydrocolloids contribute to food stability?

Hydrocolloids can improve shelf life, prevent syneresis (the separation of liquid from a gel), and stabilize emulsions in various food systems. They can enhance the physical and chemical stability of food products, ensuring their quality and prolonging their shelf life.

How are hydrocolloids used in food formulation and processing?

Hydrocolloids are used as functional ingredients in food formulation and processing to achieve desired textural attributes and stability. They can be added during mixing, cooking, or manufacturing processes to modify viscosity, control water binding, and improve product consistency.

How can hydrocolloids be beneficial in different food industries?

Hydrocolloids have wide applications in various food industries, including bakery, dairy, beverage, and sauces and dressings. They can help achieve desired texture, stability, and sensory properties in products such as cakes, yogurts, drinks, and sauces, among others.

What should be considered when using hydrocolloids in food formulation?

When using hydrocolloids, factors such as the specific hydrocolloid type and dosage, processing conditions, and compatibility with other ingredients should be considered. Formulation considerations should also include the desired textural attributes, stability requirements, and sensory expectations for the final product.

Comments, please:

We would apprecaite hearing from you. Please add your comments below. We will reply to them.

See: The Hydrocolloid Glossary

For further reading:Exploring How Hydrocolloids Affect Food Shear, Compression, or Extension

About the Editor

About the Chef Edmund: Chef Edmund is the Founder of Cape Crystal Brands and EnvironMolds. He is the author of several non-fiction “How-to” books, past publisher of the ArtMolds Journal Magazine and six cookbooks available for download on this site. He lives and breathes his food blogs as both writer and editor. You can follow him on Twitter and Linkedin.

|

About the Author Ed is the founder of Cape Crystal Brands, editor of the Beginner’s Guide to Hydrocolloids, and a passionate advocate for making food science accessible to all. Discover premium ingredients, expert resources, and free formulation tools at capecrystalbrands.com/tools. — Ed |

- Choosing a selection results in a full page refresh.